Installation of Underground GRP pipe

Pipes will be installed as per the guidelines provided in the international standard AWWA M45 which is summarized below.

Trench Excavation

Excavation of trenches will be carried out to ensure that sides will be stable under all working conditions and dewatering will be carried out. The depth of the trench will be as required depending upon the stiffness class of the pipe

Bedding

Bedding shall be prepared by the compaction of native soil, wherever required bedding shall be prepared by compaction of crushed and graded rocks.

Laying

Pipes will be handled as per the requirement laid down by the manufacturer. Pipes will be placed in the trench conforming to the required elevation, slopes and alignment. Bell holes will be provided at the mechanical joints. In cases where the pipe needs to be laid in a curvature angular joint deflection will be maintained within the specified limit.

Joining

Pipes will be joint by various methods like Coupling Joint, Lamination Joint, and Mechanical joint and lock joint. Coupling joint will be carried out as per the manufactures recommendation so as not to exceed specified angular deflection.

Lamination joint will be carried out using the hand layup method as well as the wrap around method as required. Joint will be designed to ensure it meets the required pressure and stiffness class. In cases where not specified the joint resin shall be same as the pipe resin.

Types of Joints

- Lamination Joint

- Rubber Seal Lock Joint (RSLJ)

- Rubber Seal Joint (RSJ)

- Adhesive Joint (TB/TS and CB/CS)

- Coupling Joint

Backfilling and compaction.

Embedment material will be placed so as not to disturb or damage the pipe. Hunching will b e carried out prior to backfilling. Backfilling and compaction will be done in layers maintaining the circularity of the pipe.

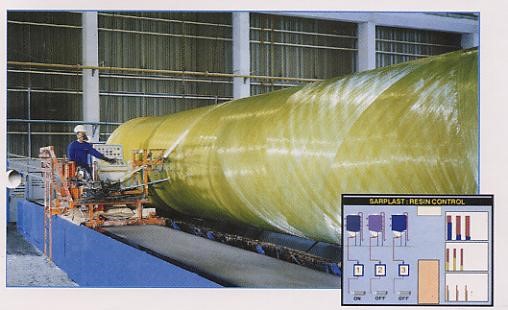

Installation of Aboveground GRP pipe

Pipe will be laid on the support and lamination will be carried out. Thrust Blocks where required will be built on pipe.

Every pipe will be supported by at least two cradles and anchored at one of these. The remaining cradle will be designed as guide, allowing longitudinal expansion of the pipe but restraining lateral movements. For pipes supported in more than two cradles, the cradle closest to the middle of the pipe will be used as an anchor. The anchors will be located with regular spacing in order to ensure even distribution of longitudinal pipe expansion on the joints.

The inside of the cradles will be covered with a 5 mm thick cradle liner to avoid direct contact between pipe and cradle. Liners will be made from materials that are resistant to the actual environment like EPDM. High friction liners will be applied at anchors while low friction liners shall be applied at guides. The pipe supports are designed as anchors or guides. Anchors are designed to restrain pipe movement. Guides are designed to allow the pipe to expand in the longitudinal direction but restrain it from any lateral displacement.

Aboveground pipes will be supported appropriately to withstand the actual load caused by

- External and environmental loads

- Weight of pipe and fluid

- Reaction forces caused by internal pressure

- Friction induced in couplings and against guides in case of temperature and/or pressure variations.

Repair of GRP Pipe

Typically, damaged pipe can be repaired quickly and easily by qualified personnel at a jobsite. The repair design depends on the wall thickness, wall composition, application, and the type and extent of damage

Structural fracture of the pipe wall is evaluated on a case-by-case basis to provide repair sufficient to restore the original pipe strength.

Repair of damaged or leaked GRP Pipes will be carried out using similar type of resin and glass as that of original pipe. The damaged section of the pipe will be either repaired by overlay after grinding off the damaged area or the pipe section will be cut off, a new pipe will be introduce and laminated.

Similarly leaks from the joint will be repaired either by replacing the joint with the new one or through lamination. New connection will be provided from the existing line by providing appropriate branch and saddle.

Tanks and Spool

Design, manufacture and supply of different types of GRP Spools, Tanks and Fittings like Segmented Bends, Tess, Branches and Reducer for different applications. These spools will be made from different resin (GRP, GRE, GRV) as per the application, also will be provided in different pressure class.

Both Horizontal and vertical storage tanks in various capacity will be provided for different fluid like Raw water, Potable water and Sea water.

Similarly underground fuel storage tank can be supplied. Fiberglass fuel storage tanks can be used to store gasoline, aviation fuel, gasohol (90% gasoline and 10% ethanol mixture), Jet fuel, Diesel, potable water and waste water at ambient underground temperature. Fiberglass tanks are impervious to the effects of external corrosion. As fiberglass tanks are not susceptible to corrosion they are maintenance free.

Lining

Lining will be done as an anti corrosive barrier layer for interiors of tanks, process equipment as well as Concrete floor.

The lining will be done either by Hand lay up or spray layup and different resin, namely polyester, Vinyl ester and Epoxy, will be used as the application may require.

Lining of surface is normally required when it is subjected to corrosive chemical or environment, lining protects the surface hence increase the service life.

Both Horizontal and vertical storage tanks in various capacity will be provided for different fluid like Raw water, Potable water and Sea water.

Grating

In places where the service fluid or the spillage is corrosive, steel grating does not provide a long service life and has to be replaced frequently in such places GRP gratings are used. GRP grating are available in various sizes and shape as the application may require. Theses gratings are resistance to acidic as well as alkaline environment. They are available in various resins system like polyester, Vinyl ester and Epoxy.

Fiberglass Grating products have become a viable replacement for many traditionally metal items such as galvanized grating and stair platforms and industrial flooring. There are many advantages that Fibreglass Grating has over metallic materials. Fiberglass Grating does not corrode, it is easier to work with, requires no painting, and can incorporate abrasive substances to reduce slips, quite apart from being easier to work with than metals.

Available in a wide range of panel sizes, colors and depths ranging from 12 mm up to 50mm. The fiberglass grating is corrosion resistant, fire resistant, anti-slip, impact resistant and lightweight

Third Party inspection of long term GRP pipe tests.

Providing Inspection at various stages of long term test like HDB test, Strain Corrosion and Creep test also verification of calculation to predict the long term properties of GRP pipes as per the guidelines in ASTM standards mentioned below.

ASTM D2992: Standard practice for obtaining Hydrostatic or Pressure design basis for fiberglass pipes and fittings.

ASTM D2584: Destructive Examination – Gel Test

ASTM D2583: Hardness Test